HOME / Track & Trace/ Dairy Industries

Dairy - Track & Trace

Securing Dairy Products with Track & Trace Solutions

Track and trace systems in the dairy industry ensure product safety, quality, and authenticity across the supply chain. By incorporating Holoprint technology, dairy products are secured with tamper-proof holographic labels and unique identifiers. This enhances transparency, combats counterfeiting, and boosts consumer confidence in dairy products.

-

Ensuring Freshness and Safety in Dairy Products

Ensuring Freshness and Safety in Dairy Products

Track and trace systems monitor the movement of dairy products from production to delivery, ensuring freshness. This reduces spoilage risks and ensures safety for consumers.

-

Compliance with Dairy Industry Regulations

Compliance with Dairy Industry Regulations

Track and trace systems help meet regulatory requirements such as cold chain management and food safety standards. They provide accurate records to ensure compliance with local and international guidelines.

-

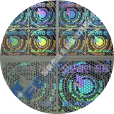

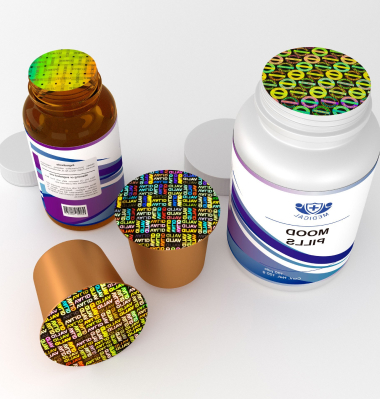

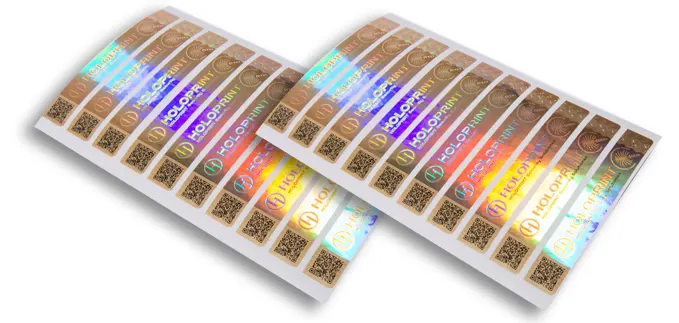

Holoprint Technology for Dairy Product Authentication

Holoprint Technology for Dairy Product Authentication

Holoprint integrates tamper-proof holograms and QR codes on dairy packaging. These secure labels prevent counterfeiting and enable easy verification of product authenticity. -

Combating Counterfeit Dairy Products

Combating Counterfeit Dairy Products

Counterfeit dairy products harm brand reputation and consumer health. Holoprint technology prevents such issues by providing secure, traceable packaging solutions.

-

Supply Chain Transparency in Dairy Industries

Supply Chain Transparency in Dairy Industries

Track and trace solutions provide real-time insights into dairy supply chains. This ensures that products are handled and transported under optimal conditions.

-

Building Consumer Trust with Transparent Systems

Building Consumer Trust with Transparent Systems

Consumers can scan Holoprint-enabled QR codes to check product details such as source, production date, and quality certifications. This fosters trust and strengthens brand loyalty.

Technical document

Contact Sales Persons

Product Serialization

Each dairy product is assigned a unique identifier for tracking purposes. This enables efficient management and recall processes when necessary.

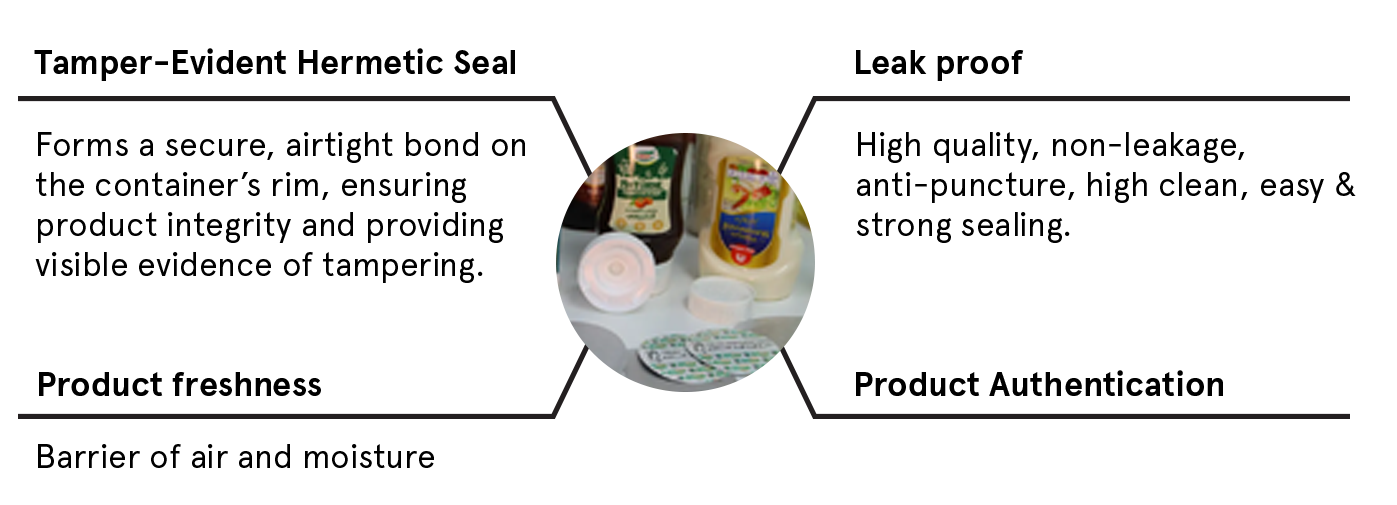

Secure Packaging with Holoprint

Holoprint holograms provide tamper-evident seals on dairy packaging, ensuring product integrity throughout the supply chain.

Cold Chain Monitoring

Track and trace systems monitor temperature-sensitive dairy products to ensure they are stored and transported under ideal conditions.

Authentication Features

Holographic labels and QR codes embedded in Holoprint technology make it easy for stakeholders and consumers to verify product authenticity.

Real-Time Data Insights

Dairy supply chains benefit from real-time tracking of product movement, ensuring transparency and accountability at every stage.

Sustainability Tracking

Track and trace systems monitor sustainable practices, such as ethical sourcing and waste reduction, throughout the dairy production process.

Regulatory Compliance Assistance

These systems ensure compliance with food safety regulations, such as those set by the FDA or EU, simplifying audits and inspections.

Consumer Interaction and Education

Holoprint-enabled codes allow consumers to access detailed product information, promoting awareness and engagement with the brand.

ADVANTAGES OF DAIRY INDUSTRIES

Enhanced Food Safety

Track and trace systems quickly identify and isolate contaminated dairy products, ensuring consumer safety and minimizing health risks.

Prevention of Counterfeiting

Holoprint technology protects against counterfeit dairy products, preserving brand reputation and consumer trust.

Improved Supply Chain Efficiency

Real-time data enables faster identification of bottlenecks and inefficiencies, ensuring timely delivery of fresh dairy products.

Simplified Compliance with Regulations

Accurate records and traceability make it easier to comply with food safety standards and cold chain requirements, avoiding penalties.

Strengthened Consumer Trust

Consumers gain confidence in dairy products by verifying authenticity and quality through Holoprint-enabled labels.

Support for Sustainability Goals

Track and trace systems help the dairy industry monitor and improve sustainability practices, reducing waste and promoting eco-friendly processes.

Holograms are three-dimensional images created through the interference of laser light to produce a visually striking and often interactive effect. While holograms are most commonly associated with artistic and decorative applications, they can also be used in information technology (IT) solutions in various ways

RFID Technology

Radio Frequency Identification (RFID) tags can be embedded in products, allowing for real-time tracking and verification of the product’s authenticity.

Holograms are three-dimensional images created through the interference of laser light to produce a visually striking and often interactive effect. While holograms are most commonly associated with artistic and decorative applications, they can also be used in information technology (IT) solutions in various ways

RFID Technology

Radio Frequency Identification (RFID) tags can be embedded in products, allowing for real-time tracking and verification of the product’s authenticity.

Holograms are three-dimensional images created through the interference of laser light to produce a visually striking and often interactive effect. While holograms are most commonly associated with artistic and decorative applications, they can also be used in information technology (IT) solutions in various ways

RFID Technology

Radio Frequency Identification (RFID) tags can be embedded in products, allowing for real-time tracking and verification of the product’s authenticity.

Holograms are three-dimensional images created through the interference of laser light to produce a visually striking and often interactive effect. While holograms are most commonly associated with artistic and decorative applications, they can also be used in information technology (IT) solutions in various ways

RFID Technology

Radio Frequency Identification (RFID) tags can be embedded in products, allowing for real-time tracking and verification of the product’s authenticity.

Holograms are three-dimensional images created through the interference of laser light to produce a visually striking and often interactive effect. While holograms are most commonly associated with artistic and decorative applications, they can also be used in information technology (IT) solutions in various ways

RFID Technology

Radio Frequency Identification (RFID) tags can be embedded in products, allowing for real-time tracking and verification of the product’s authenticity.

Holograms are three-dimensional images created through the interference of laser light to produce a visually striking and often interactive effect. While holograms are most commonly associated with artistic and decorative applications, they can also be used in information technology (IT) solutions in various ways

RFID Technology

Radio Frequency Identification (RFID) tags can be embedded in products, allowing for real-time tracking and verification of the product’s authenticity.

Ensuring Milk Product Authenticity with Serialized Tracking

Track and trace solutions in the dairy industry allow for serialized identification of every milk packet, carton, or bottle, ensuring product authenticity and consumer safety. By integrating QR codes or RFID tags on packaging, each product can be traced back to its origin, processing unit, and distribution path. This level of transparency deters counterfeiting, helps detect supply chain inefficiencies, and ensures that only quality-assured products reach the consumer. In case of contamination or regulatory non-compliance, affected batches can be identified and recalled swiftly. The result is improved brand credibility and enhanced food safety assurance across the dairy value chain.

Real-Time Monitoring for Cold Chain Compliance and Freshness

Track and trace systems in the dairy sector also play a crucial role in monitoring temperature and handling conditions throughout the cold chain. IoT-enabled sensors and scannable tags allow real-time logging of storage and transportation data to ensure freshness and compliance. This helps prevent spoilage, ensures timely delivery, and reduces product loss due to temperature breaches. Regulatory authorities and distributors gain greater visibility over product movement and condition, improving accountability. Such data-driven logistics enhance consumer confidence in the quality and freshness of dairy products.

WHAT PEOPLE SAY

Find out why people love working with Pearl Business LLC

We are true to ourselves, and commit to always perform at our best.

We believe that we are outstanding. Not because we say it, but because we work hard at it. We are dedicated, committed and focused. We believe that every person will reach their personal best and overcome any challenge through a shared culture and ethos.

Frequently asked questions

Holoprint Security Solutions (Holostik group) having more that 40 years of experience in developing and providing anti-counterfeiting solution for various industries. And Holoprint is the first manufacturing plant for holographic products from the Middle East region located in Dubai, UAE.

Our clients have experienced an ROI of up to 339% on our anti-counterfeiting products.

Holoprint has end-to-end in-house capabilities for R&D, product design, manufacturing and IT development.

We invest a minimum of 5% of our annual budget on research and development.

Case Study

LABELS – B

View more

Ba industry

View more

SECURITY HOLOGRAMS – Special Features With Description

View more

HOT STAMPING FOIL (HSF)

View more

Tax stamps

View more

SHRINK SLEEVES

View more

LABELS – A

View more

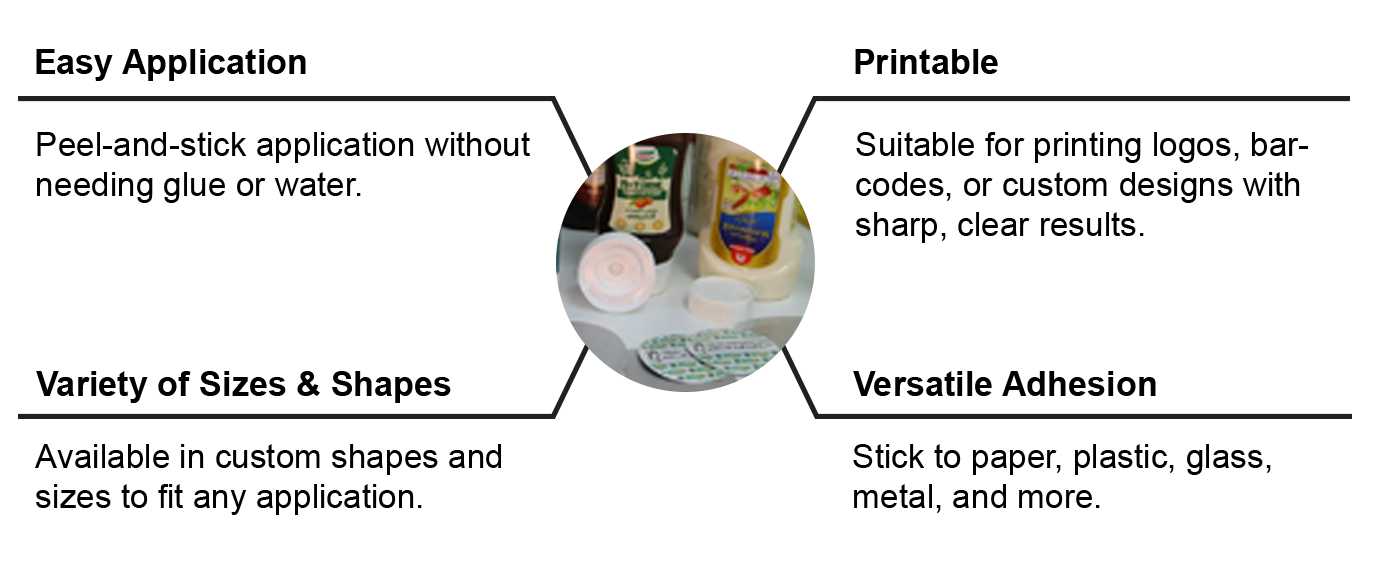

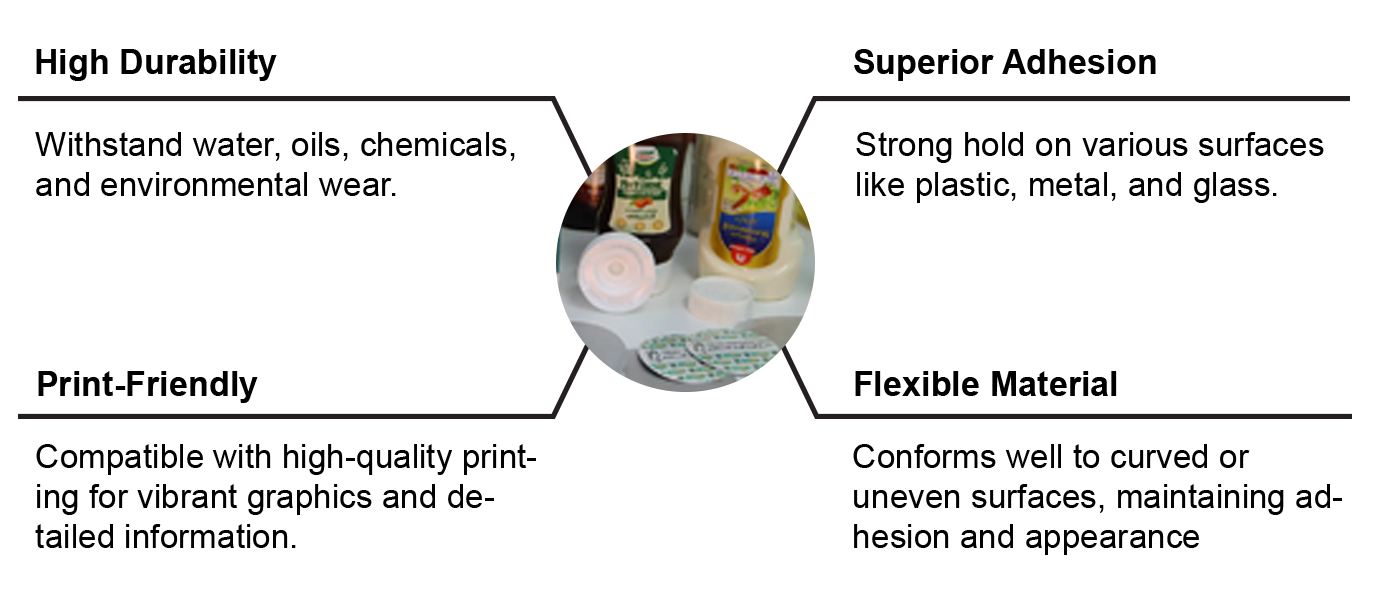

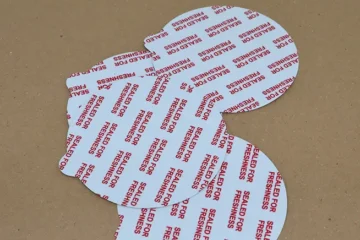

WADS / INDUCTION LINERS

View more

SECURITY HOLOGRAMS & OVDS

View more